Paris metro relies on E³

posted on 23rd Aug 2024 09:27

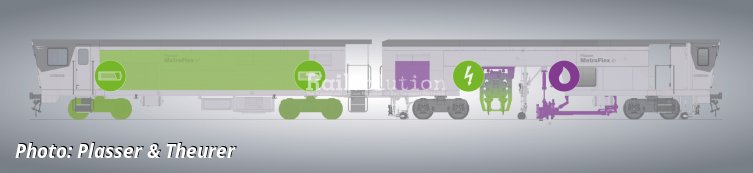

Plasser & Theurer's E³ technology has been around for ten years now. As of 2026 TSO, the 97-year-old French construction company, will be in charge of maintaining the Paris metro network on behalf of RATP Group, the operating organization. In order to make this work more environmentally friendly in future, TSO has ordered two battery-powered tamping machines from the E³ series. The two Plasser MetroFlex E³ machines feature several innovations: as there are several rubber-tyred lines, a special tamping concept was necessary. This is because the traction rails which the rubber wheels travel on are an additional obstacle while tamping.

The E³ drive system specially designed for this form of urban rail uses various conductor rails as a source of power instead of the overhead contact line, which is commonly used for heavy rail. The batteries are charged either via the conductor rails or via their own charging plug. Because conductor rails are switched off while tamping, an innovative battery system supplies the vehicle with power.

It is a perfect solution for the tight time window in which the metro is not in service, i. e. between 01.00 and 05.30 h. Additionally, working without polluting is particularly beneficial, especially in tunnels. It also makes workspaces more attractive and lowers health risks for staff. Furthermore, the new drive system reduces fine dust, as it can also be used for electro-dynamic braking. Work is also significantly quieter thanks to the low noise levels of electric actuators.

Innovation partnership

RATP Group, TSO, and Plasser & Theurer have all signed an MoU. In the end, the new Plasser MetroFlex E³ machines should also be used efficiently to ensure the highest possible availability of tracks. The three companies are working together to evaluate how modern measuring technology and digital tools can be integrated into maintenance. With fixed-point measuring included, tamping machines take the inner and outer track geometry into account while working. More precise knowledge of railway tracks is the basis for optimizing costs, quality, and time requirements.

The new Plasser MetroFlex E³ machines are an additional milestone in the ten-year success story of E³, with more than 14 machines using power from the overhead contact line for tamping, stabilizing, and profiling or using battery power to install and maintain overhead contact line systems. An additional 60 E³ machines are currently being produced. Whether it’s heavy rail or regional networks: sustainable infrastructure maintenance for rail, the climate-friendly mode of transport, is the future.